The metallization consists of a high vacuum deposition of a thin layer of aluminium.

This process takes place in a dedicated environment with controlled air at a pressure of 10¯⁴ Torr.

With this procedure, at a low environmental impact, we get a high quality reflective finish, particularly appreciated in the lighting market, or in applications where an aesthetic appearance is required (i.e. cosmetics).

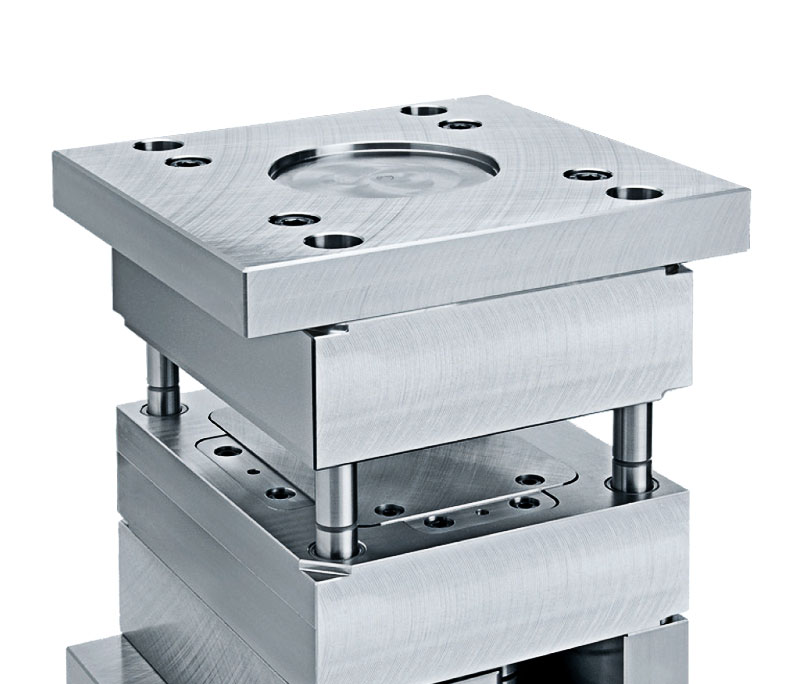

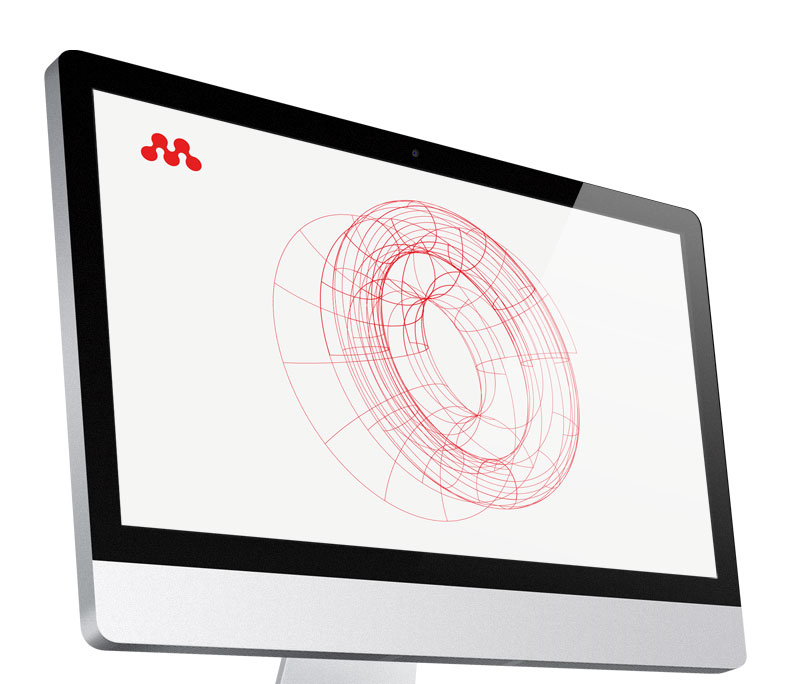

The complexity of the process and related issues are taken into account early during the mould design and construction, in order to identify and solve potential problems with the aim of reducing scraps and maximizing production time.

For each piece to be metallised, a specific piece of support equipment is designed and manufactured, that allows on the one hand fast piece positioning and on the other a complete surface metallization. In some cases it is possible to get a partial metallization by masking the piece.