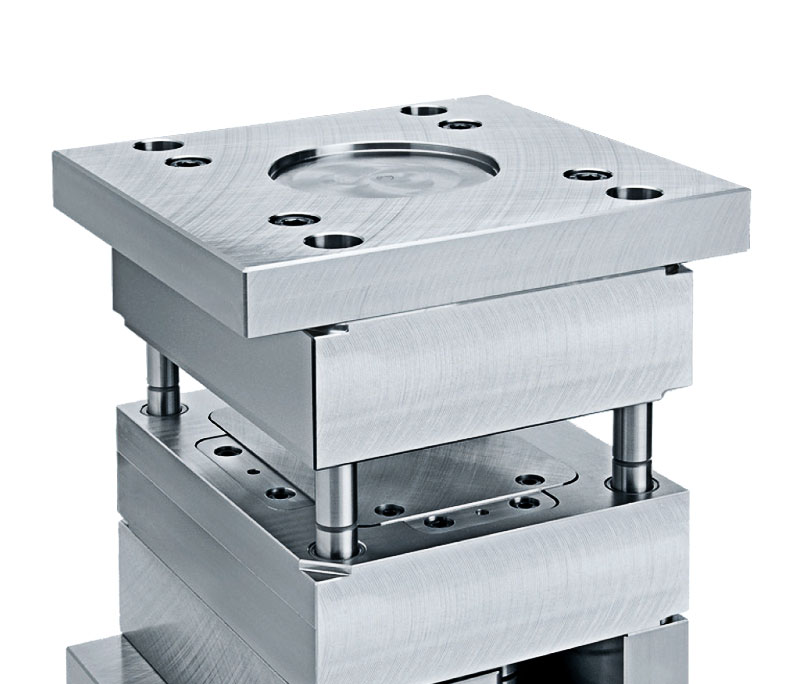

The injection mould for plastic materials is the pivot on which the entire production process runs.

For our clients this is the most critical investment, linked to the quality of the moulded part and the mould lifespan.

This sets us apart from other players in the market and enables us to retain our customers in the long term.

In facing this challenge, MAXPLA presents a modern and dynamic tool shop where milling machines, 3 and 5 axes, are managed by DELCAM software, while the EDM‘s and a POLI brand measurement center complete the range of main machines.

Translating the mould design into real mechanical operations of mould construction, is not only a task for software and automated machinery. Once again the experience and expertise of our staff, together with the collaboration of our suppliers, remains the best tool we provide to our customers.

Beside our presses, we have an independent workshop totally dedicated to the maintenance of the thousand moulds in our warehouse. Our firm has a precise commitment to our customers which guarantees a life-long functionality of the moulds.