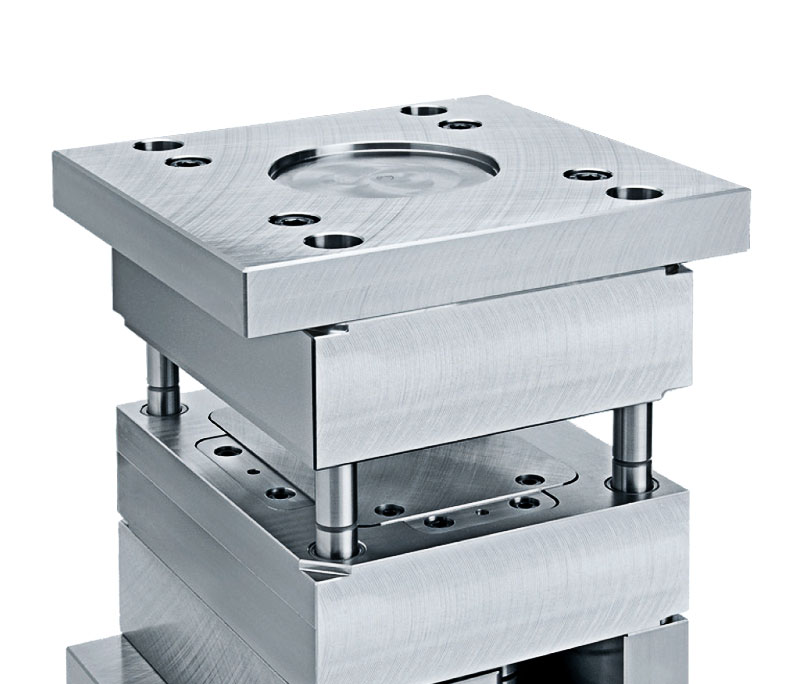

Plastics injection moulding consists of transforming thermoplastic polymers into mass-produced articles of high quality.

The company has 18 fully robotized presses, some of them with magnetic plates for faster mould changes.

The clamping force varies from 50 up to 720 Ton, the latter with decentralization of injection and one 150 Ton press for moulding of bicomponent material.

Working in a continuous cycle of 3 shifts, all the operating units are programmed and planned with NICIM system for order scheduling, which enables continuous production monitoring and therefore full compliance with terms of delivery agreed with our customers.

Maxpla operates more than 200 different types of polymers ranging from the most common materials to high performance polymers such as:

ABS – PC – PA – PEEK – PET – ULTEM – SURLYN – POM – EVA